For professionals in commercial poultry, including farm operators, equipment installers, and manufacturers, the stability of the barn environment is non-negotiable. A sudden power outage can lead to catastrophic bird losses within minutes due to panic, smothering, or rapid temperature changes. While a large diesel generator offers long-term power, there is a critical delay—the gap between the utility power failing and the generator successfully starting and taking the load. This transitional period, often a few seconds to a few minutes, is where a dedicated backup battery system becomes an indispensable safety and welfare asset.

The question of “how long will a battery backup last?” is not about weeks, but about providing immediate, critical light for a defined duration. szAMB addresses this necessity with the Master & Slave Control Battery Back-up system, engineered to manage this specific, high-risk window and prevent the panic that leads to mortality.

Defining the Runtime: Critical vs. Extended Backup

The runtime of a poultry house backup battery is not standardized; it is entirely determined by its intended function and the required load. Unlike whole-house residential battery systems designed to run refrigerators or HVAC units for hours, the primary purpose of an integrated poultry lighting battery backup is short-duration, high-impact relief.

The Primary Function: Bridging the Power Gap

The core purpose of the backup battery is to provide immediate, low-intensity light—typically 1 to 2 lux—to prevent total darkness. The absence of light causes instantaneous panic and clustering in the flock, leading to fatal smothering. The battery must last long enough to cover two specific scenarios:

- Generator Transition: Providing light during the 1-to 5-minute period required for the primary standby generator to start, stabilize, and transfer the load from the utility line.

- Short-Duration Outage: Sustaining minimal lighting for very brief outages (under 15 minutes) where a generator startup would be inefficient or unnecessary.

For these critical scenarios, commercial poultry battery systems are often designed to provide 30 minutes to 2 hours of minimal light. This duration is sufficient to stabilize the flock, allow the generator to assume the load, and give personnel time to safely enter the barn and assess the situation without the immediate threat of bird panic.

Factors Determining Actual Runtime

The actual runtime of the szAMB backup battery system is mathematically determined by system design, balancing capacity against the load:

Factor | Description | Impact on Battery Runtime |

Battery Capacity (Ah/kWh) | The total energy the battery can store. | Directly Proportional: A higher capacity battery provides longer runtime. |

Emergency Load (Watts) | The power drawn by the lighting fixtures in low-power emergency mode. | Inversely Proportional: Lower light intensity settings (e.g., 1 lux) maximize runtime. |

Depth of Discharge (DOD) | How deeply the battery is discharged before recharging. | Higher DOD (deeper discharge) can reduce the battery’s overall lifespan in years. |

Temperature | Environmental heat/cold in the barn. | Extreme temperatures can reduce a battery’s short-term output and long-term lifespan. |

Because the szAMB system only powers the lights at a minimal emergency level (1-2 lux), the power consumption is drastically reduced, enabling the battery unit to provide the required short-term coverage reliably.

The szAMB Master and Slave Controller: An Integrated Safety Solution

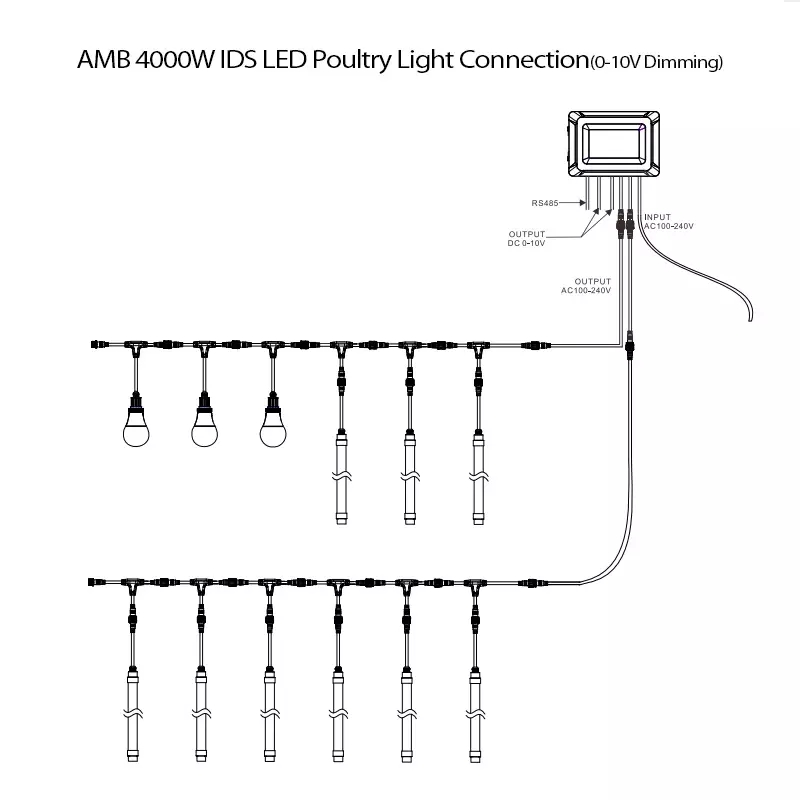

The effectiveness of the backup battery is entirely dependent on the control system that manages it. The szAMB Master & Slave Control system transforms the battery from a simple power source into an intelligent, automated fail-safe mechanism.

Seamless, Automated Transition

The master and slave controller provides instant, automated response upon power failure. The moment the controller detects a drop in AC mains power, it automatically commands the entire network of slave lighting fixtures to switch their power source to the integrated battery system. This transition is immediate, and flicker-free, and ensures that the lights never go completely dark. The Master unit acts as the intelligence, managing both the utility power and the battery reserve, prioritizing welfare by preventing the sudden dark shock that triggers panic.

Lifespan and Reliability of the Battery

While the runtime of the backup may be short (e.g., 30–120 minutes), the battery’s overall operational life is significantly longer. Modern industrial batteries, particularly sealed Lead-Acid or lithium-ion variants used in commercial backup systems, are often rated for 5 to 10 years of usable life before their capacity drops below a critical threshold (e.g., 70% of new capacity). Since the szAMB system only uses the battery in rare, emergency instances, it experiences minimal wear cycles, maximizing its multi-year service life. The system also integrates battery health monitoring to ensure the unit is always optimally charged and ready for immediate deployment.

Commercial Resilience and Return on Investment

For commercial stakeholders, the battery backup is an investment in risk mitigation. The cost of a few hours of downtime pales in comparison to the value of an entire flock. In a worst-case scenario, the backup battery functionality provided by the szAMB master and slave controller prevents catastrophic losses and downtime.

This system is engineered for continuous commercial operation. The master and slave controller ensures that the automated lighting schedule—including precise sunrise/sunset dimming and photoperiod control—is protected. The battery-backed Real-Time Clock (RTC) ensures the programmed cycle remains perfectly intact during the power failure, meaning that once the main power or generator is restored, the flock is seamlessly transitioned back to the precise point in their lighting schedule. This continuity prevents hormonal shock and maintains the strict lay or growth schedules that drive profitability.

Conclusion

A poultry house battery backup system is designed not for endurance but for immediate stability. When integrated via a master and slave controller, the back up battery is engineered to last the critical duration required to prevent panic and facilitate the safe activation of the main generator.

The szAMB Master & Slave Control system with Battery Back-up provides this essential, fail-safe layer of protection. By instantly providing low-level, flicker-free light, it protects the flock, maintains the integrity of the lighting schedule, and ensures operational continuity, making it an indispensable component of any modern, risk-managed poultry facility.

Contact szAMB today to integrate this reliable emergency solution into your lighting infrastructure and secure the welfare and capital of your operation.