For commercial poultry operators, equipment manufacturers, and agricultural lighting dealers, understanding the biological clock that governs egg production is crucial for optimizing barn management and production schedules. The specific time a hen lays her egg is not random; it’s a predictable event tightly linked to her circadian rhythm and, critically, the lighting for laying hens provided in the barn.

The short answer is that the vast majority of chickens lay their eggs in the early morning hours, typically within six hours after sunrise (or the lights turning on). This consistency allows large-scale operations to standardize collection and manage flock health efficiently.

The Biological Clock and the Laying Cycle

The timing of the lay is governed by the hen’s reproductive cycle, which lasts approximately 24 to 26 hours. The entire process begins with the release of a new yolk (ovum) from the ovary, an event known as ovulation.

The Light-Dependent Trigger

Ovulation usually occurs about 30 minutes after the previous egg was laid, but this crucial process is inhibited by darkness. The hen’s brain requires a light stimulus—a perceived “sunrise”—to trigger the release of Luteinizing Hormone (LH), which initiates the next ovulation. Because the cycle is slightly longer than 24 hours (25-26 hours on average), the time of lay naturally shifts a little later each consecutive day. This continues until the calculated ovulation time falls into the dark period. When this happens, ovulation is delayed until the next morning’s light stimulus, allowing the cycle to reset. The hen will then skip a day of laying before starting a new clutch (a sequence of consecutive laying days) early the following morning. The consistent timing of the lay—being laid during the first half of the light period—is due to the fact that forming the egg (yolk formation, albumen addition, and shell calcification) takes roughly 25 hours inside the hen’s reproductive tract. For operations using specialized lighting for laying hens, where the light is typically set to come on between 4:00 AM and 6:00 AM to achieve the necessary 14–16 hour photoperiod, the peak laying period is generally concentrated between 6:00 AM and 12:00 PM.

The Spectral Requirement

For this photoperiodic control to work optimally, the light must not only be bright enough but must also possess the correct wavelength. The red light spectrum (long wavelength) is paramount because it can penetrate the hen’s skull to stimulate the hypothalamic photoreceptors deep within the brain. This spectral quality ensures the hormonal trigger for ovulation is consistently strong, maintaining a tight, predictable laying schedule and maximizing clutch length.

The szAMB Advantage: Precision LED Lights for Laying Hens

For large-scale producers, consistency in lay time is vital for efficient egg collection, reducing cracked eggs, and managing feed distribution. The use of advanced, customized LED lights for laying hens is essential to control the photo-environment and ensure this precise timing is maintained year-round, regardless of external weather or season.

szAMB (Folewo) provides engineered LED lights for laying hens that support peak production through technical precision and unmatched durability. Our systems are designed to directly address the environmental variables that impact the laying cycle, beginning with precise light management parameters.

Parameter | Recommended Setting | szAMB Solution Feature |

Photoperiod | 14–16 Hours of Light | Guarantees consistent light duration for maximum persistency. |

Intensity | Stable 10–30 lux | Dimmable systems maintain stable light, reducing stress. |

Spectrum | Red Light Bias | Engineered output optimizes critical red wavelengths for photostimulation. |

Transitions | Gradual 30-minute ramps | Flicker-Free, smooth dimming simulates sunrise/sunset. |

We offer precise photoperiod control, ensuring the hen receives the critical 14–16 hour light duration needed to initiate and maintain strong laying persistency. This is paired with Spectrum Optimization, where our systems are engineered to output the necessary red spectrum wavelengths required for maximum reproductive stimulation.

Crucially, our fixtures feature advanced Flicker-Free technology and 100-0% smooth dimming capabilities. Chickens have a much higher flicker fusion rate than humans, meaning poorly controlled lights cause significant stress. Our flicker-free systems prevent this stress and, through the smooth dimming, allow for the gradual simulation of natural sunrise and sunset. This natural transition reduces stress, prevents panic, encourages hens to use perches at dusk, and provides a gentle, predictable start to the laying day, thereby reinforcing the circadian rhythm.

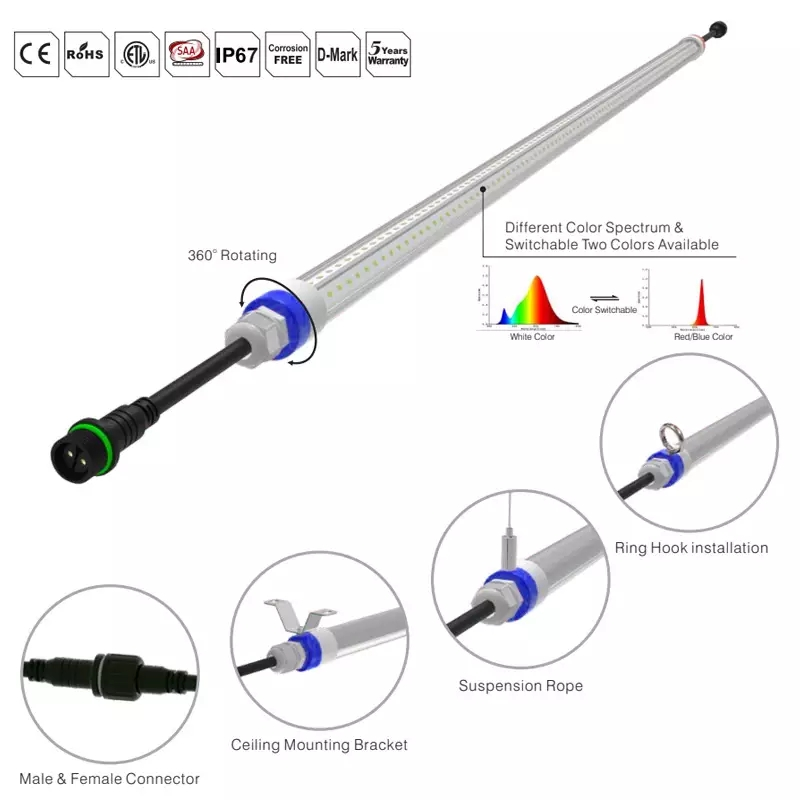

Finally, the durability and longevity of the hardware are key for uninterrupted operation. Laying hen environments are highly corrosive. szAMB’s fixtures, such as the T8 LED lighting solution, are built with specialized, ammonia-resistant housing. They boast an IP67/IP69K rating, certifying complete protection against dust, moisture, and high-pressure washdowns used during sanitation. This robustness ensures long-term operational stability and guarantees a lifespan of over 80,000 hours, offering a critical return on investment for large-scale operations and equipment suppliers.

Key Management Practices for Consistent Laying

Optimizing the timing of the lay involves more than just selecting high-quality LED lights for laying hens; the light schedule must align with overall barn management practices to maximize consistency.

The first critical step involves ensuring uniformity of light. The entire house must receive uniform illumination; dark spots can delay the light stimulus, leading to uneven laying times and potential floor egg issues. szAMB’s T8 LED solutions are specifically designed for wide distribution and minimal light variation across the entire facility. The second vital practice concerns the timing of feed delivery. Feed should be scheduled to encourage consumption early in the light period because hens need adequate calcium intake from the feed hours before the shell is formed in the uterus (shell gland). Maximizing early feed access directly supports strong shell quality and the predictable timing for the morning lay. Finally, for logistical efficiency, the egg collection schedule must be timed to coincide with the peak laying hours in the mornings. Collecting eggs promptly helps reduce the dwell time of eggs in nest boxes, thereby minimizing contamination and preventing breakage or damage.

For manufacturers and large farms seeking to maximize efficiency, utilizing reliable, customized LED lights for laying hens is the foundation of a controlled environment. szAMB systems provide the durability and precision control necessary to ensure consistent egg quality and timing, directly boosting operational returns.

Contact szAMB today to learn how precision lighting for laying hens can standardize your flock’s laying schedule and improve egg collection logistics.